The Problem:

We had a prospective customer contact us to help them with their paint performance. Their current product applied and looked good but when the parts were put outside, they started rusting within days. They were having claims and disgruntled customers that threatened their business and reputation.

The Solution:

There are as many variables in our customer’s work as there are in how they do it. At Marcus Paint, we understand this. To provide a coating that meets the needs of our customers, we must first understand the entire process – every unique and not-so-unique activity. We conducted a thorough on-site line survey by our Technical Account Managers (TAM) in order to determine the conditions that would directly affect the performance of the coating.

Our custom formulation process began after we obtained information from the line survey. Based on the results of the production analysis, our R&D chemists developed the most effective formulation tailored to meet the unique requirements of their production process. Throughout the production process, we engaged the customer at every milestone to ensure that the end product would meet the customer’s needs – always considering the limitations of the production line and maximizing the efficiency of the manufacturing process.

The Second Problem:

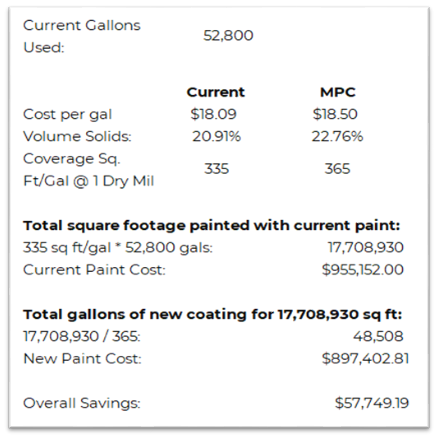

Once we had the final formulation our sales department presented the test results – and the selling price. This is where the second problem began. Our product price per gallon was $18.50 whereas our competitor’s price was $18.09. With an estimated use of 52,800 gallons per year, our product was going to cost them over $20,000 in paint spend. The big difference here was that our volume solids were 22.75% and our competition was 20.91%.

Before we do the math there are a couple of basic facts that we need to explain. Volume solids is the percentage of the paint that is composed of non-volatile materials, such as pigments and resins. These non-volatile ingredients are what give the paint its color, durability, and adhesion. The cost per square foot is the cost of the paint per unit area and is calculated by dividing the total cost of the paint by the total square footage of the surface to be painted.

The Math:

The current gallons used show a paint spend of $18.09 * 52,800 gallons = $955,152. If the volume solids of both coatings were equal the paint spend would increase to $18.50 * 52,800 = $976,800. When you add the increase in volume solids of the new coating there is a significant change in the overall customer cost. Increasing the volume of solids causes an overall decrease in the amount of paint needed to coat the same number of square feet. This results in a new total cost of $18.50 * 48,505 = $897,402. This is a savings of $57,749 dollars per year.

Results:

Upon passing our internal specifications, a trial prototype sample was manufactured and run at the customer’s production facility. In addition to our customer service team, we also sent our sales, technical account managers, and lab personnel onsite to evaluate the application, appearance, and cure properties and to confirm that we met or exceeded their expectations. After 30 days outside the parts looked almost brand new. With our consultative approach and product solution, our new customer was extremely satisfied.

Through regular technical account manager visits, we continue to evaluate our customers’ needs to identify value opportunities, productivity improvements, and performance enhancements. Our team is proud to work harder, think smarter, and put more effort into satisfying our customers than anyone else in the industry. With our proactive approach, we are able to serve as an indispensable business partner rather than just a coating supplier.