Problem

There are many factors to consider when choosing a proper paint for your unique requirements, including a proper color and gloss match, meeting performance requirements, and environmental considerations.

In the category of application, one element to properly define and control is the viscosity of the paint. It must be carefully aligned with the process of application.

This is important because it determines how the paint will perform when applied with different application methods such as dip, spray, flow-coating, vacuum coating, and roll coating. Paint that is too viscous (thick) can create ridges, uneven areas due to reduced flow out and leveling, heavy drips, sags, etc. Paint that is too thin can cause issues with inadequate coverage, substrate hiding, runs, drips, etc. A paint that is either too thick or too thin will most certainly cause appearance and performance issues.

Improper paint viscosity could also lead to/cause damage to application systems, components, and equipment.

Solution

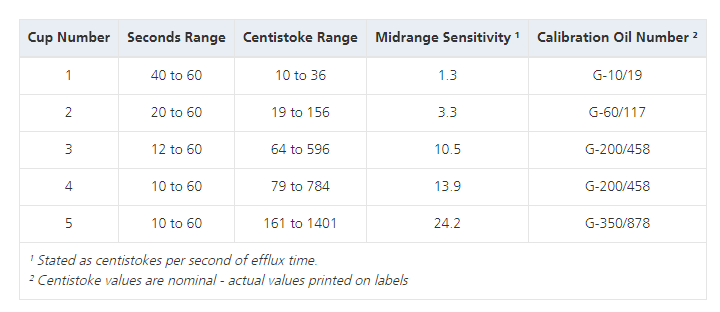

For most paints, a device known as a viscosity cup is used to read and validate the proper thickness of the paint. Viscosity cups are generally classified as Shell or Zahn type.

Viscosity cups have a “cup” that holds a specific amount of paint and a long handle for keeping the paint steady in the cup while the viscosity is measured with a stopwatch. At the bottom of the cup is a small “precise size” hole, cup size dependent, that allows the paint to stream through until there is a “first” break in the stream at 4 inches off the bottom of the cup. It is the amount of time (typically measured in seconds) that determines the paint’s level of viscosity. Manufacturers specify a viscosity at 77 degrees F. Marcus Paint Company often provides Viscosity/Temperature conversion charts to assist operators online.

If a viscosity adjustment is needed, you should consult the Technical Data Sheet or call your Technical Representative.

Results

Viscosity is but one of many items we monitor with our customer’s application lines, but it is one of the most essential to avoid poor application quality online and costly rework.

Marcus Paint Company has and maintains a very proactive approach to all our customer’s needs, and requirements. We continually evaluate our customers’ application process through regular technical service on-site visits to ensure our customer’s finish quality is to the standard agreed upon. We provide training and training materials: work instructions/operating procedures, troubleshooting guides, system daily quality sheets, sample analysis as well as continuous improvement development initiatives, and unsurpassed customer service.